Precision mechanics has as a fundamental prerequisite the evolution and improvement of production processes, this involves both the more specifically production phases (upgrades of CNC machinery, use of latest generation equipment and tools, etc.) but also the design and pre-production phases.

The updating and improvement of production processes therefore also involve updating the design tools.

Digital Twin

OMC Costruzioni Meccaniche has long since completed the migration of the design phase from the classic 2D field to the three-dimensional one, in particular to parametric 3D design; this has allowed us, over time, a significant leap in quality in the precision of the components produced, both at the level of individual parts and of entire machine, but also a significant reduction in the time required to pass from the virtual prototype to the actual realization, allowing us to being extremely versatile in developing new components as well as being able to respond quickly to requests for customization of components and machinery already designed.

For years now, our technical department has relied on the Autodesk design technologies that led us to the realization of “Digital Twin” of what is produced in our departments.

“Digital Twin” concept was introduced for the first time in 2001 by Michael Grieves, today Chief Scientist for Advanced Manufacturing at the Florida Institute of Technology, and this concept puts in a close and direct relationship what has been developed in the “virtual space” (design phase) with what is produced in the “real space” (construction phase), not only at the level of mere planning aimed at obtaining the documentation for the subsequent realization (the production drawings, in the case of mechanics), but integrating also metadata capable of providing essential information on materials, physical characteristics, etc., with the possibility of integrating other design environments (eg. development of electrical wiring and PLC logic or PLM and ERP management systems).

CAM 3D Software

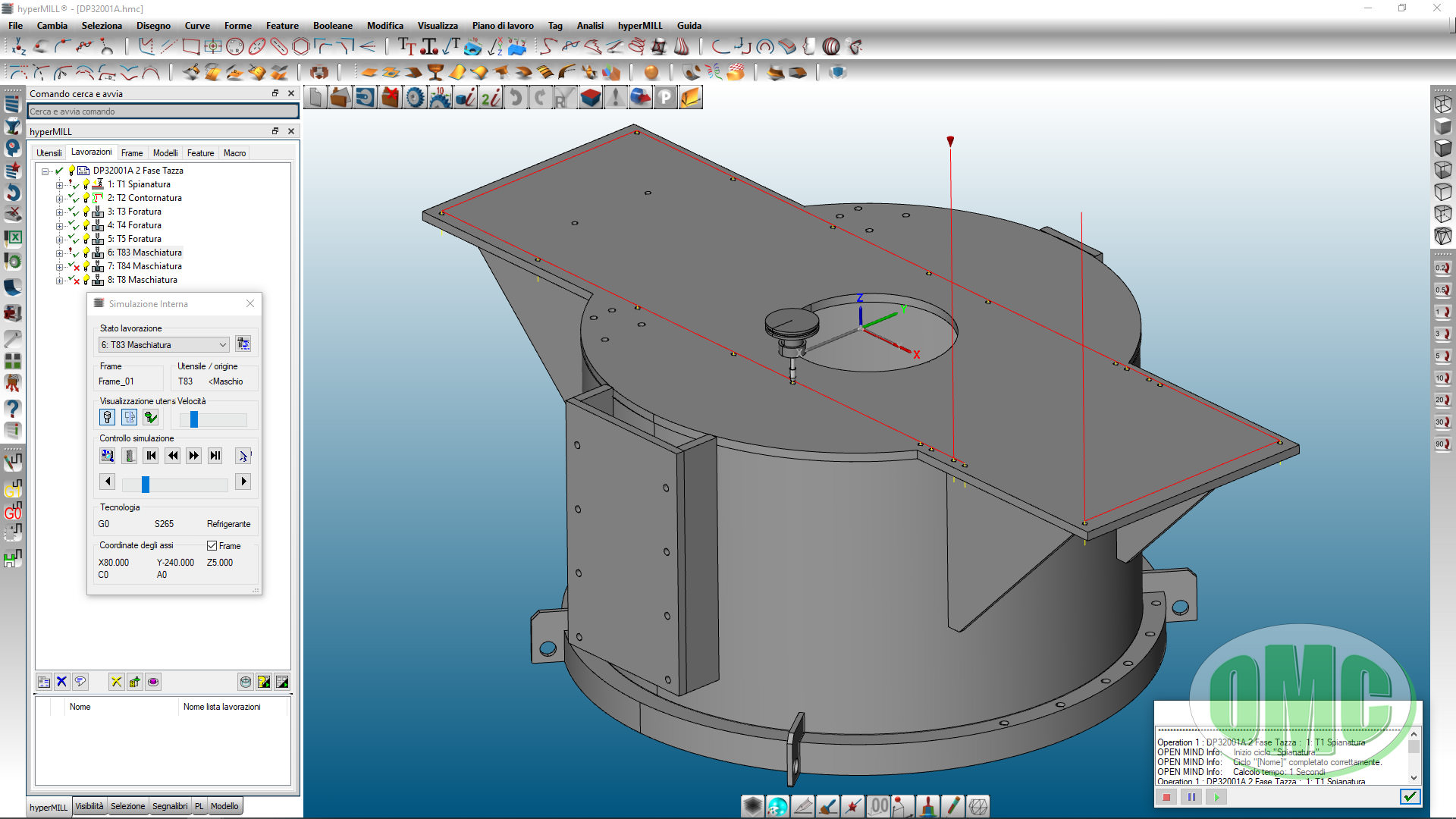

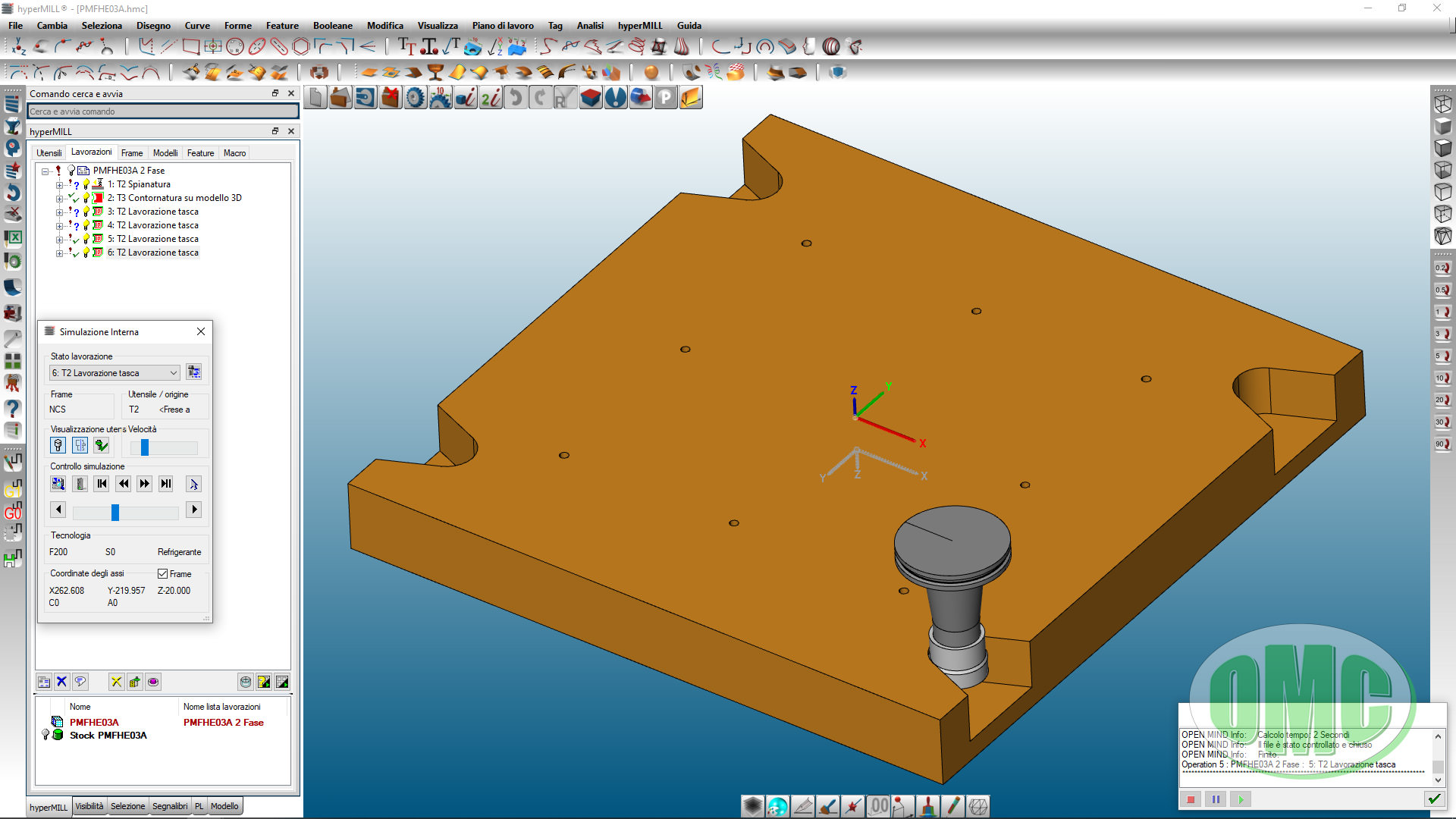

The natural next step for OMC Costruzioni Meccaniche could only be the integration of a CAM (Computer Aided Manufacturing) solution capable of making the transition from CAD design to the creation of the finished product even more direct, precise and integrated.

After a long and careful research, the choice fell on hyperMILL, a CAM solution developed by Open Mind that stands out for its wide range of 2.5D, 3D and up to 5-axis milling, drilling and turning modules, distinguishing itself for its significantly reduced programming times, as well as the efficient use of modern CNC machines and consequently longer tool life.

The hyperMILL CAM software is particularly popular in the automotive supply chain, for example in Volkswagen, as well as in industry in general, but it has also been used from Ramco Machine, LLC (Rowley, MA, USA) for the production of components for NASA thanks to the quality of the 5-axis machining strategies.

Thanks to this new important investment in the integration of new technologies for our technical office, OMC Costruzioni Meccaniche maintains its constant commitment to increase and evolve its production capacities, improving the quality and precision of the components and machinery produced, the collaboration with its partners, suppliers and customers and remaining extremely competitive thanks to the optimization of design and production processes.