In mechanics, metal welding is one of the most widespread machining processes in the world; there are different welding methods and technologies, each one suitable for specific applications, among which the most used for workshop work is certainly M.I.G./M.A.G. welding.

OMC Costruzioni Meccaniche has recently bought new M.I.G./M.A.G. multi-purpose generators SINCOSALD NOVASTAR SPEED series which represent the most recent and updated Inverter-based welding technology.

The new generators use the latest generation of Insulated-gate bipolar transistors (IGBTs) and digital arc welding control for exceptional performance and high repeatability in welding processes, they also allow the use of new welding programs:

- Growth in 25% of the welding speed.

- Lack of spatters and perfect arc control.

- Smooth welding and always without incisions.

- Great weld penetration obtained by a very intense arc.

- This procedure allows the costs reduction for the parts preparation.

- The welding geometry is regular without spatters.

- Minimum joint deformations.

Thanks to the use of the latest generation of equipment, OMC Costruzioni Meccaniche can guarantee high quality and reliability of the components produced, to the full advantage of the end customer, and at the same time significantly reducing the times of the various production processes without compromising flexibility.

M.I.G./M.A.G. Welding or arc welding with metal under gas protection

Arc welding with gas protection on the metal involves the use of a continuous wire electrode which melts under a protective gas cover which has the function of protecting the welding zone from the influences of the surrounding atmosphere.

This type of welding offers various possibilities of application in terms of material, degree of mechanization and welding position and lends itself to the union of almost all weldable materials, moreover it is a particularly versatile process so as to allow the union of thin sheets (starting from 0,8mm) or of thick sheets, besides being able to be performed either with manual torch or with the help of automated systems such as portals or robots.

M.I.G. (Metal-Arc Inert Gas)

M.I.G. means the welding process of high alloy steels and alloys such as aluminum, magnesium, nickel and titanium based materials with the aid of an inert gas (eg. Ar – Argon or He – Elio).

M.A.G. (Metal-Arc Active Gas)

M.A.G. means the welding process of alloyed and unalloyed steels with the aid of an active gas (eg. CO2 – Carbon Dioxide).

Shielding Gas

The shielding gases used in the M.I.G.-M.A.G.welding procedures are essentially of two categories: inert and active. Argon, helium and argon-elium mixtures belong to the first category, while gases such as carbon dioxide, argon mixtures with oxygen or carbon dioxide are defined as active.

Argon (Ar)

Inert gas, produced by the fractional distillation of the atmosphere, extracted from the air through cycles of successive compressions and expansions that bring the temperature of the gas to such values as to allow it to be liquefied. It allows to have a good stability of the arc and an easy trigger; thanks to the low thermal conductivity, the central part of the arc column is maintained at high temperatures making the drops of material more fluid.

Helium (He)

Inert gas, rather rare, scarcely present in the atmosphere and obtained from the subsoil. By using this gas there is less arc stability but greater penetration; its use is predominant in welds on large thicknesses and on materials with high thermal conductivity such as, for example, copper and aluminum. Being very volatile, more gas is needed to ensure the correct welding protection.

Carbon Dioxide (CO2)

Active gas present both in the air and in the subsoil.

The most widespread problem caused by the use of this type of protection is to cause the formation of excessive spatter and the establishment of an unstable arch; the creation of a rather short arc and of constant length allows however to have a good control of the same, moreover it allows to have good penetrations in the material.

Active Mixtures

Mixtures of previous gases are often preferred, for example Argon-Oxygen, Argon-Oxygen-CO2, Argon-CO2. Pure inert gases are capable of performing the protective action at any temperature, but the addition of active gases improves arc stability and the transfer of metal from the electrode wire to the melting bath, without affecting the protective action.

Transfer Modes

In the M.I.G./M.A.G. welding procedure the methods of transferring the filler metal from the wire-electrode to the melting bath depend, in addition to the electrical parameters of welding, also on the diameter of the wire, on the type of generator used and on the gas used; based on these parameters, the drops can be transferred with the following methods:

Short-Arc

(Immersion Transfer, Dip-Transfer or Short Circuit)

The filler metal is transferred to the melt bath in the form of drops that plunge into the bath itself, creating continuous short circuits. This transfer is characterized by the presence of currents up to 200A, from the use of thin solid wires, from 0.6 mm to 1.2 mm, thus making it possible to weld small thicknesses and welding in all positions. It is obtained with direct current generators.

Spray-Arc

(Spray Transfer)

The drops of filler material are “sprayed” into the melt bath due to the high current, creating a continuous flow of material. This characteristic is obtained with direct current generators with currents higher than 200A and wires with a diameter greater than 1 mm. A very fluid and very penetrating melt bath is generated, suitable for welding in a flat position, above all on medium and large thicknesses

Pulsed-Arc

(Impulse Transfer or Pulsed Arc)

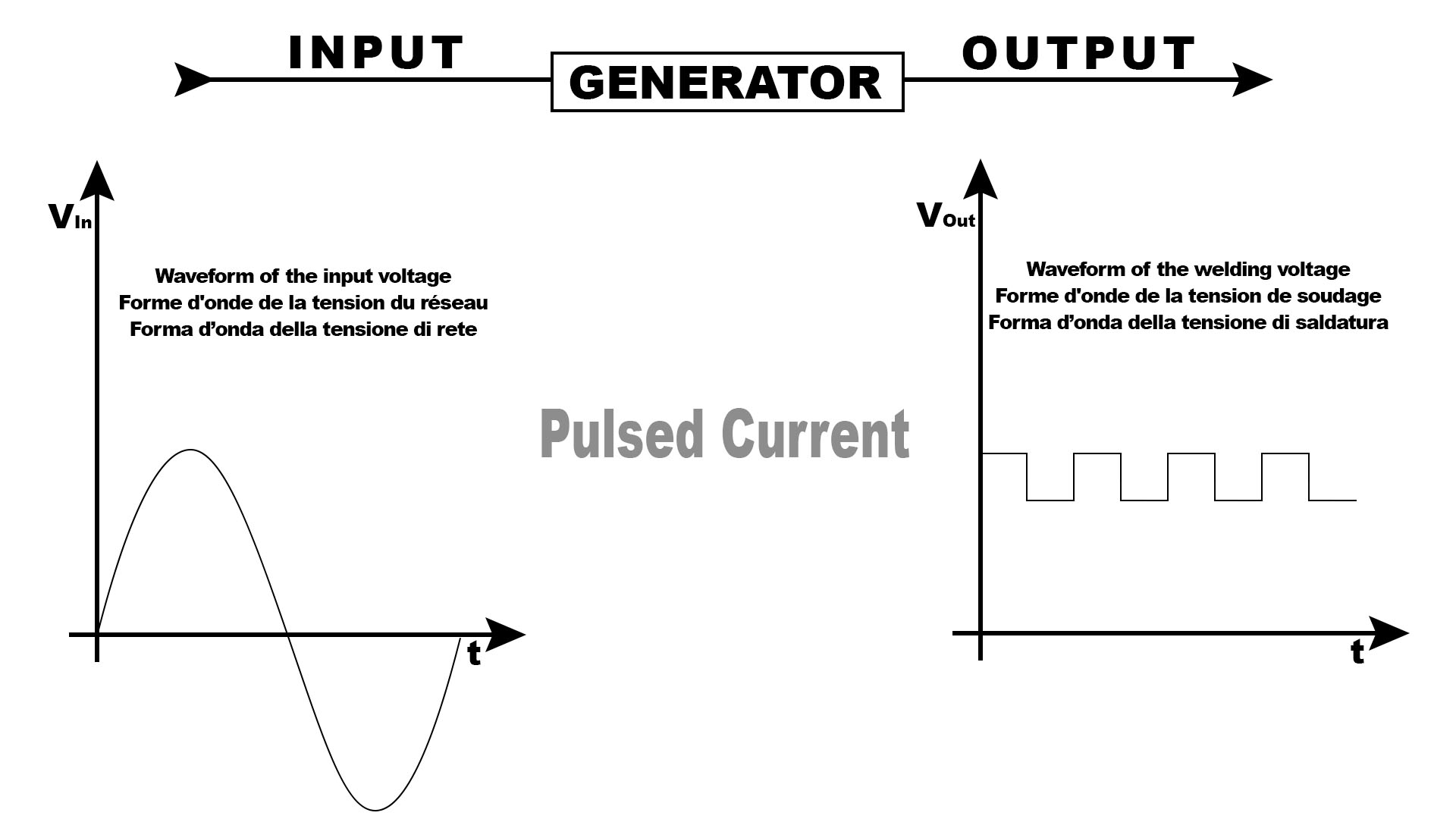

This procedure can only be obtained with pulsed current generators, where pulsed current causes small drops to separate and allows to obtain the characteristic of the Ppray Arc, but with lower currents; also the thermal contribution, the dimensions of the bath and penetration are very similar to Spray Arc. Particularly used with materials such as aluminum or stainless steel, where the Short Arc process does not guarantee sufficient results.

Welding Wires

The welding wires can be distinguished on the basis of their chemical composition and the morphology of their section which can consist of only metal (solid wires) or with an inner core containing granules (cored wires).

The solid wires generally have the same composition of the base material, with the addition of elements that can help in the cleaning of the base material; the diameters of common use are 0.6 – 0.8 – 0.9 – 1 – 1.2 – 1.6 mm.

The cored wires are not made of solid metal but are internally filled with granular powder; this has the same functions as the electrode coating.

The cored wires, compared to the solid wires, have more stability of the arc and deeper penetrations, guarantee a better appearance of the joint, eliminating in many cases the finishing work (eg. grinding of the spray) and reducing the risk of defects such as porosity; naturally the use of animated wires requires the removal of the slag, as for the M.M.A. electrode welding; the diameters of common use are 0.6 – 0.8 – 0.9 – 1.2 – 1.6 mm.

Current Generators

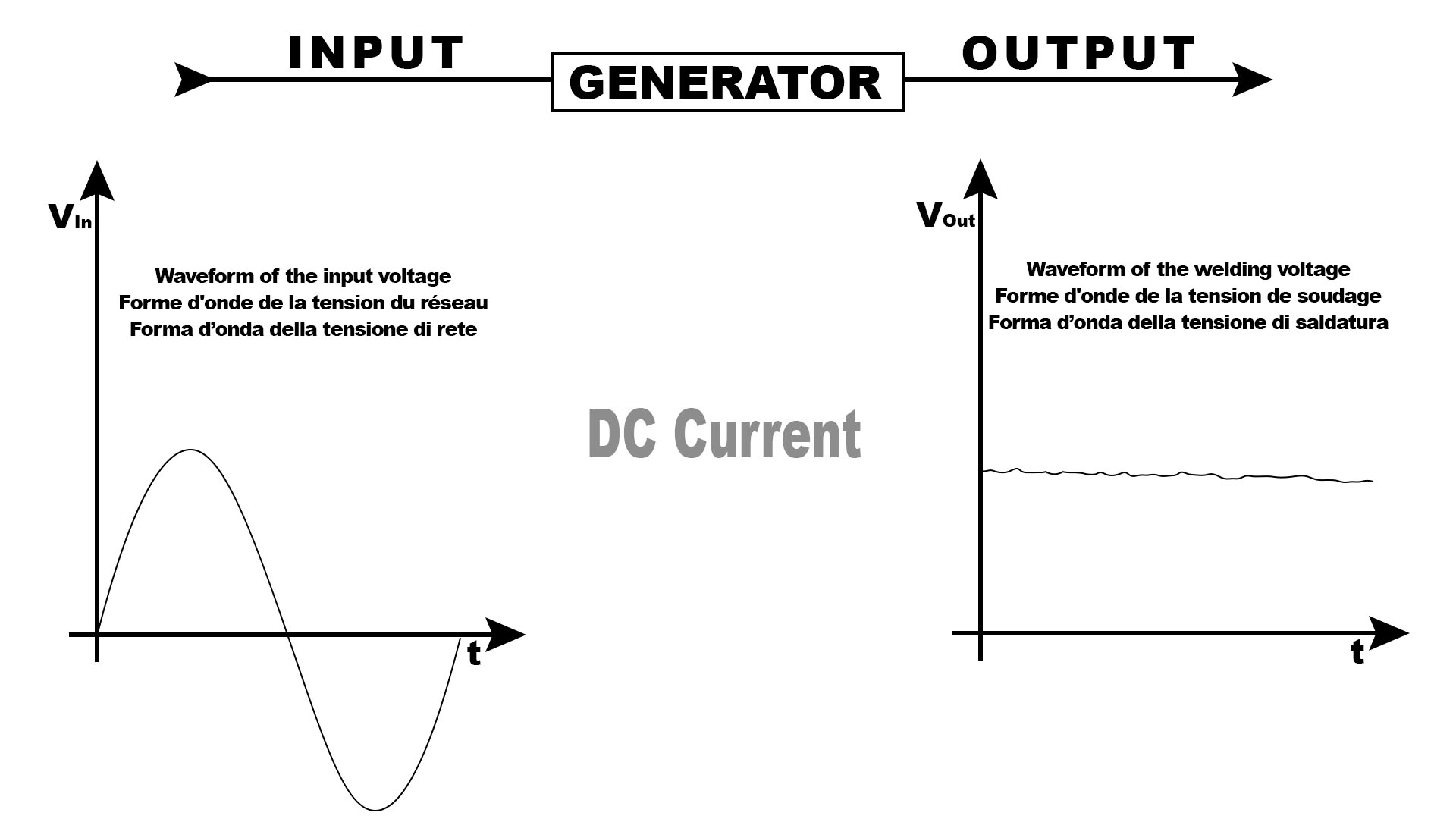

DC Continuous Current

The continuos current generators are the most widespread and are characterized by a high stability, in fact the electric arc powered at constant voltage and generated on a wire expelled at a constant speed tends to naturally stabilize. The parameters of the tension and the wire speed can be selected with a certain tolerance given the flexibility of the process, in this way the transfer of the drops can be obtained both with the Short Arc and Spray Arc procedures.

Pulsed Current

In this case the generator no longer regulates the voltage, but rather the current, which is modulated with a train of pulses (hence the name “pulsed”) which have the purpose of forcing the detachment of the drop from the filler material; in this case, pulses and wire speed must be well synchronized to obtain an acceptable welding.

Once the type of current generator has been determined, also the different connection of the poles of the welding source to the material to be welded determines different working methods:

- Continuous Current With Direct Polarity

The torch is connected to the negative pole and the material to be welded to the positive pole of the supply source: this type of connection is used only in welding with cored wires. - Continuous Current With Reverse Polarity

The torch is connected to the positive pole of the supply source and the material to be welded to the negative pole of the supply machine: this is the most frequently used connection.

The Materials

Sweet, carbon steels

The carbon steels are welded with direct current and reverse polarity, applying exclusively the M.A.G. welding process, the applications range from the use of only CO2, to the Ar-CO2 mixtures in various percentages (the most common is 80% argon, 20% CO2), the higher the percentage of Argon present in the mixture, the better the characteristics and the stability of the arc.

The welding characteristics are very good, especially with Short Arc technique, where consistent welding baths are obtained, that allow applications in all positions. it is necessary to prepare the joints with bevel with thicknesses higher than 3 mm.

Stainless steels

The stainless steels are welded with direct current or pulsed current with reverse polarity applying exclusively the M.A.G. welding process, the shielding gas used must be composed of Ar + CO2 or Ar + O mixtures, the percentage of Argon must not however be lower than 98% of the mixture to avoid strong oxidation of the chromium present in the base material.

The thicknesses of the joints over 2.5 mm must be beveled; the filler material must be particularly suitable for the quality of the stainless steel to be welded, furthermore the grinding of the points is recommended for the execution of a good weld.

Aluminum and its alloys

Aluminum and its alloys are welded with direct current or pulsed current with reverse polarity by applying the M.I.G. process; the shielding gas used is generally pure Argon, but pure Elio or Ar + He mixture can also be used.

For flat welding, regardless of thickness, the Spray-Arc and/or Pulsed-Arc technique is used; instead the Short-Arc technique is used to weld thin thicknesses in vertical and angled positions.

Given the characteristics of aluminum, it is advisable, rather than grinding, to mill the points themselves.

Other materials

The M.I.G./M.A.G. welding process is also used on materials such as nickel and its alloys, copper and its alloys; direct current with reverse polarity is used for all these.

To weld copper on thicknesses greater than 5 mm, it is advisable to use the M.I.G. process, considering however that the current intensities must be regulated according to the welding position and the thickness of the joints.