Slide plates in special anti-wear steel (Hardox).

Easy installation on all types of medium and large-sized presses.

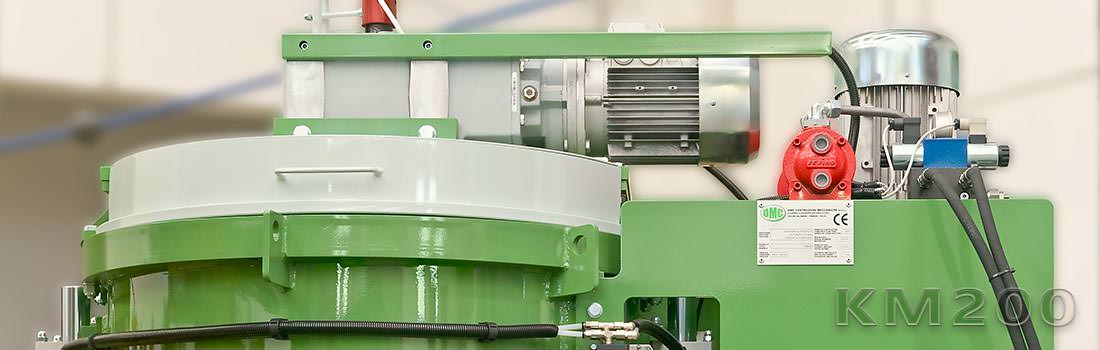

Designed and built to distribute a perfect and constant dosing of 1st layer mortar inside the molds of the press. Equipped with slide plates in special anti-wear steel and independent hydraulic unit that controls, by hydraulic cylinder, the movement of the dosing cups from the loading position to the unloading.

The dosing is in line through a drawer fitted with buckets calibrated for every format: in loading position the buckets are filled with the right amount of mortar and then are moved linearly to the unloading position by the hydraulic cylinder.

To facilitate unloading, a pneumatic solenoid valve controls and directs a jet of air inside buckets, ensuring a perfect dosing.

Equipped with planetary group with epicycloidal rotation to mix the aggregates, constructed with robust gears in hardened steel and equipped with two agitators and a peripheral scraper which guarantee the correct and rapid dosing, maintaining the mixture always soft.

Complete with level probe for the eventual block of the press and the recall of the mortar from the mixer.

Technical Features

Automatic Batcher built to distribute the mix of 1st Layer:

The usable capacity is about 200 Lt;

The overall weight is about 1.200 Kg;

The installed power is 7,0 kW.